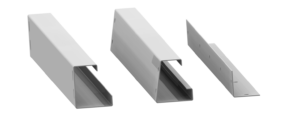

Our facility specializes in producing profiles according to drawings, specifications, or designs provided by the client. Thanks to our experience, we can advise you on standard solutions as well as our own custom designs. The wide range of shapes achievable with RBT's machinery allows us to better adapt to our clients' needs.

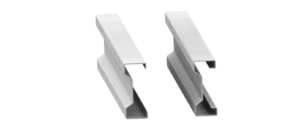

Here are examples of how the produced profiles can be used:

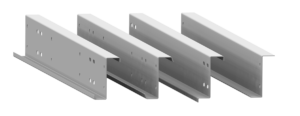

Structures for mounting photovoltaic (PV) modules – C and Z profiles.

Buildings such as: production halls, industrial facilities, warehouses, storage units, agricultural buildings, office buildings, commercial spaces, sports facilities, or, for instance, timber-framed houses.

The most commonly used materials for producing cold-formed profiles at RBT are:

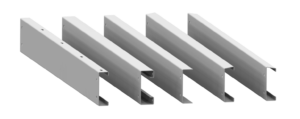

Cold-Formed Perforated Profiles

Declaration